Haya Qazi

In recent months, the headlines about US tariffs on China and India, and fears of an escalating trade war have overshadowed a deeper shift in the global economy: the race for rare-earth elements (REEs) and the reordering of the supply chains that underlie modern technology, defence and the green transition, says an in-depth article on the subject, published in GreaterKashmir.com.

What are rare-earth minerals?

The term “rare-earth minerals” is a group of 17 metallic elements: the 15 lanthanides plus scandium and yttrium. They are critical components in everything from consumer electronics and wind-turbine magnets to fighter jet engines and missile-guidance systems. They are characterised by high melting point, high thermal conductance, high conductivity and high density.

According to the US Geological Survey, China holds around 40 per cent of global reserves and produces nearly 70 per cent of the world’s output, which is about 270,000 of the 390,000 metric tonne mined in 2024.

Meanwhile, the US imports nearly 100 per cent of many critical minerals, including several rare-earth elements leaving it highly vulnerable to supply‐chain disruptions. China also controls 90 per cent of the world’s refining capacity.

The Bayan Obo mine in China is the largest REE mine in the world. That dominance gives Beijing not only economic leverage but geopolitical power in a world increasingly dependent on advanced technologies for civilian and military uses.

In India, rare earths are found in the monazite sand, which contains nearly 50-60 per cent of all the rare earth oxides. These are found along the coastal beaches of Andhra Pradesh, West Bengal, Odisha, Kerala, Gujarat and Maharashtra.

Utility and significance

Rare earths are nearly omnipresent in high‐technology systems: from airpods to airbags in a car, to strong permanent magnets used in electric-vehicle motors or satellite communications. They are used in all cell phone cameras, LED screens for televisions, in healthcare such as MRI machines and even some cancer drugs.

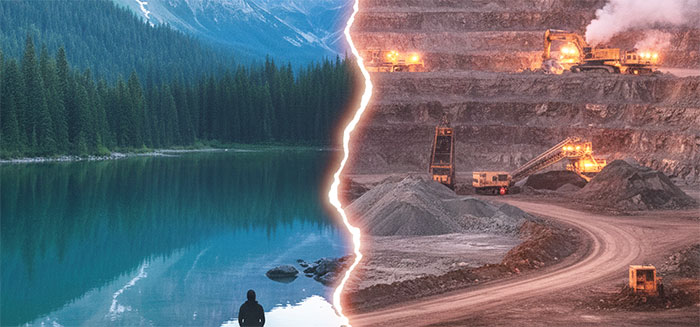

For every tonne of rare earth, 2000 tonne of waste material is produced. This presents a paradox: the same minerals essential for a low-carbon future also bring high environmental cost.

However, the mining and refining of rare earths carry significant environmental and energy‐intensity burdens. Life-cycle analyses show that extracting and processing REEs often requires high energy inputs, large volumes of water, and chemical reagents, with consequential radioactive by‐products and greenhouse-gas emissions.

For instance, one study in ScienceDirect reported that global rare-earth extraction is tied to large increases in greenhouse gas emissions. The analysis showed that greenhouse gas emissions had increased by 94 per cent in mining in 2020.

For every tonne of rare earth, 2000 tonne of waste material is produced. This presents a paradox: the same minerals essential for a low-carbon future also bring high environmental cost.

In the trade arena, rare earths have become a strategic choke point. The US imports almost all its REEs from China. When a vital supply chain is concentrated in one country, the dominant supplier can impose export restrictions, tariffs or licensing regimes that ripple through global production.

Recent reports show that China expanded export controls in 2025 to cover many rare-earth elements and will require foreign firms using Chinese-origin materials or equipment to obtain export licences from Beijing.

These moves coincide with broader trade negotiations — such as the APEC summit in November in South Korea between the Asian and Pacific nations, making clear that rare earths are no longer just a commodity but strategic tools in the new world order.

Such dynamics are forcing other nations to reconsider supply-chain resilience, to re-locate mining and refining capacity, and to reduce dependencies that may become liabilities in the global trade environment.

India’s dilemma

For India, the rare-earth question presents both an opportunity and a dilemma. On the one hand, India holds the world’s fifth-largest rare-earth reserves, about 7 million metric tonne by some estimates.

On the other hand, it lacks the mining, processing, and refining capacity required to actually use these. It is highly dependent on China for rare earth minerals, with which it already has a strained relationship.

India is proactively exploring a tie-up with Russia for rare earth minerals and processing capability — part of the country’s attempt to reduce dependence on China and to align its mineral-security strategy with geopolitics.

India Rare Earth Limited is a major player in the mining of rare earths, and has collaboration with Japan (Toyota Company). Additionally, during the recent visit of the Afghan Foreign minister Amir Ali Khan Muttaqi, he offered India to invest in the mineral resources of Afghanistan, which also include some rare earth minerals reserves.

Afghanistan has a complex relation with Pakistan, and such a project can influence India-Pakistan power dynamics in the region. At the same time, China’s tightening of export licence regime has already impacted Indian industry: the number of Indian companies awaiting rare-earth magnet import licences from China doubled recently. China reportedly also prohibited India from re-exporting the REEs to USA, thereby hampering India’s autonomy.

India is responding with ambitious policy: it has launched a seven-year national initiative to strengthen domestic supply of rare-earths and has proposed a Rs 7,350 crore incentive scheme to develop domestic magnet production.

The Indian Government is also accelerating amendments to mining laws like Mines and Minerals (Development and Regulation Act) to facilitate critical-mineral availability.

Yet the dilemma remains: India must decide whether to commit to large-scale investment in mining, refining and magnet manufacturing — with all the environmental, capital-intensive and regulatory challenges such projects entail — or to remain a user of materials processed abroad, thus leaving it vulnerable.

The author is a regular columnist for Greater Kashmir